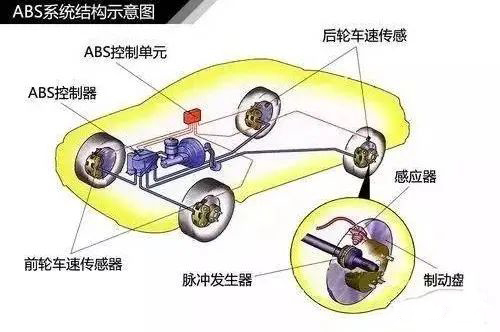

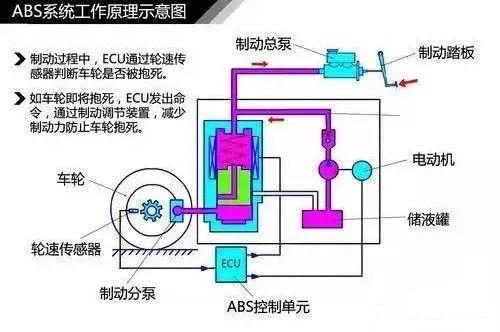

How ABS works

ABS stands for Anti-lock Brake System and can be installed on any car with hydraulic brakes. It is the use of a rubber air bag in the valve body, when the brake is pressed, the brake oil pressure is given to the ABS body, at this time the air bag uses the middle of the air compartment to return the pressure, so that the wheel to avoid the lock point. When the wheel is about to reach the next lock point, the pressure of the brake oil makes the air bag act repeatedly, so that it can act 5-10 times in a second, which is equivalent to constantly braking and relaxing, that is similar to mechanical braking.

Therefore, the ABS anti-death suppression system can avoid the direction of the emergency brake and wheel sideswipe, so that the wheel is not locked when braking, not to let the tire rub with the ground at a point, thereby increasing the friction, so that the brake efficiency reaches more than 90%, but also reduce the brake consumption, extend the service life of the brake wheel drum, disc and tire twice.

ABS wheel speed sensor function

ABS is the anti-lock braking system, which can be used to prevent the wheel from holding and dragging during automobile braking, so as to improve the direction stability and steering maneuverability during automobile braking, prevent the wheel from side-sliding and tail dumping when the wheel is locked, and give full play to the braking efficiency of the automobile. The wheel speed sensor, as the information provider of ABS, is equivalent to the human eye. The function is to detect the wheel speed, generate a sine AC signal proportional to the wheel speed, and then transform into a digital signal to the ECU, which is used to control the brake pressure regulator.

Classification and composition of ABS wheel speed sensor

Commonly used ABS wheel speed sensors can be divided into magnetoelectric wheel speed sensors and Hall wheel speed sensors.

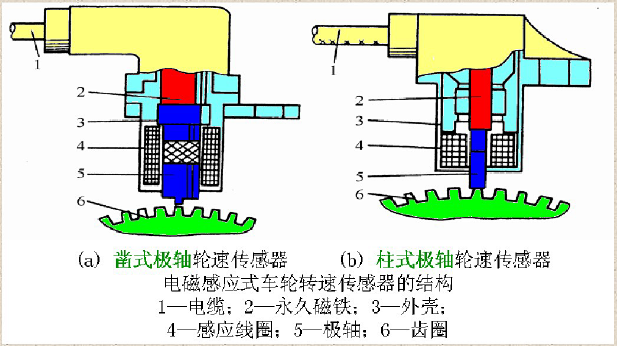

Magnetoelectric sensor composition:

According to the structural shape of the magnetic core end, it can be divided into chisel pole shaft and column pole shaft wheel speed sensor, the specific structure is as follows:

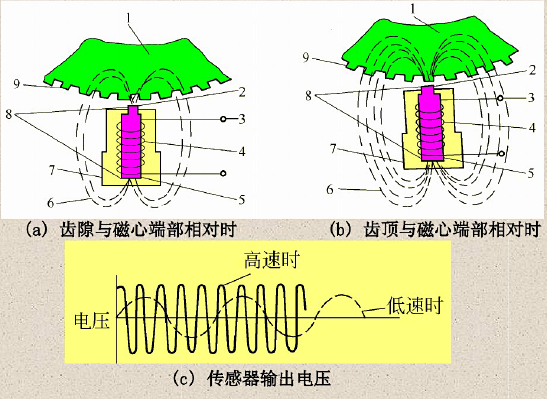

How it works: Magnetoelectric wheel speed sensors use a small AC voltage to transmit each wheel speed information to the ECU. The strength and frequency of this AC voltage are proportional to the wheel speed, and both will increase with increasing speed.

Advantages: electromagnetic wheel speed sensor has simple structure and low cost.

Cons:

1. The strength of the voltage signal transmitted by the electromagnetic induction wheel speed sensor to the ECU of ABS changes with the change of speed, and the signal amplitude generally varies in the range of 1V to 15V. When the speed is very low, if the voltage signal output by the sensor is lower than 1V, the ECU cannot detect such a weak signal, and the ABS cannot work normally.

2. Electromagnetic induction wheel speed sensor frequency response is low. When the wheel speed is too high, the frequency response of the sensor can not keep up, and it is easy to produce wrong signals.

3. The electromagnetic induction wheel speed sensor has poor ability to resist electromagnetic interference, especially when the output signal amplitude is small.

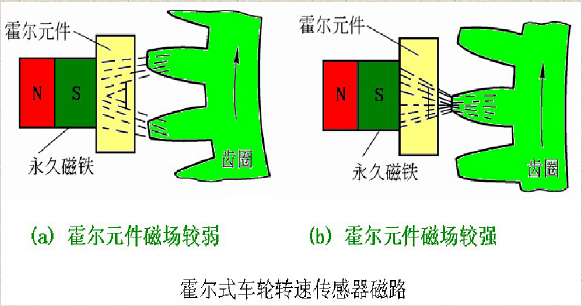

Hall-type wheel speed sensor composition and working principle:

The gear ring rotates with the wheel, the convex teeth and the backlash constantly alternately pass under the pole axis, so that the core magnetic flux changes and the alternating signal voltage is generated in the induction coil, the frequency :f=30~6000Hz, the voltage amplitude :U=1~15V.

Advantages:

1. The output voltage signal strength does not change with the speed change. Under the condition that the power supply voltage of the car is 12V, the amplitude of the signal remains unchanged from 11.5V to 12V, even when the speed is very low

2. The sensor frequency response is up to 20kHz, which is used in ABS, equivalent to the signal frequency detected when the speed is 1000km/h, so there will be no problem that the frequency response can not keep up at high speed.

3. The voltage signal output of the Hall-type wheel speed sensor does not change with the change of speed, and the amplitude is high. Therefore, the Hall-type wheel speed sensor has a strong ability to resist electromagnetic interference.